what kind of stone to use for paver base

posted on March 8, 2013 by

Who prepares the toughest brick paver bases in the Fox Cities?

Stonehenge does, of course!

And we're willing to bet that every other hardscape contractor in Wisconsin that you'd enquire would give you the same answer.

So how can we say with any potency that ours is all-time?

We do more than only read trade magazines and talk to mfg reps. We test. Side-past-side, head to head, we exam our materials and methods against the other methods and materials out there. And because brick paver patios are among our bread and amend offerings, we absolutely had to exist sure nosotros were offering our clients in Appleton, Neenah, Menasha and the residual of the Valley the very all-time, nearly durable paver installations.

And so a few years dorsum we tested all of the available methods and stone types bachelor to united states for apply as patio base of operations. We excavated an area behind our shop and prepared iv dissimilar sub-bases to test in that space. The base preparations were equally follows:

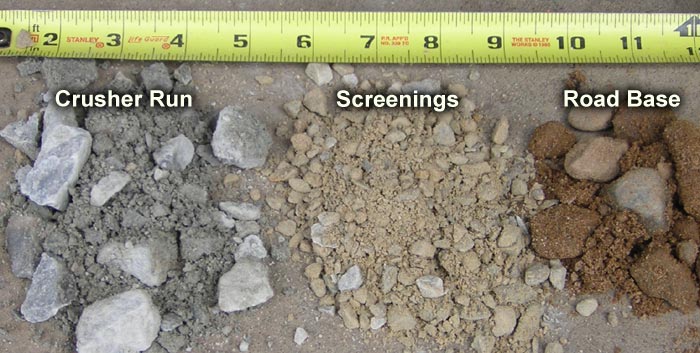

- 6″ of "crusher run" limestone (also called "iii-quarter minus", to indicate stone sizes of 3/4″ down to fine dust) topped with 1″ of coarse sand. This cloth and method are often touted equally being the all-time, but anecdotal evidence we had showed that not to exist true.

- seven″ of "screenings", which is crushed limestone of sizes 3/8″ down to fine dust. (Of notation, we are picky about where we source our screenings from – most suppliers in the expanse offering screenings with stone sizes that are too small, giving poor interlock. For this test nosotros used our favorite supplier.)

- half-dozen″ of "road base", an aggregate material mix plant mainly in northern parts of Wisconsin and used as the base for almost pavements in that location. It'south composed of rounded granite stones of approx iii/4″ mixed with a very coarse, slightly loamy sand. 1″ of coarse bedding sand topped this sub-base of operations as well.

- 7″ of coarse sand. Occasionally we hear nigh people using this as the sole material for a base of operations. We knew total well this would not hold up as a base, but we wanted empirical prove showing how poorly information technology would serve below a flexible pavement similar brick pavers.

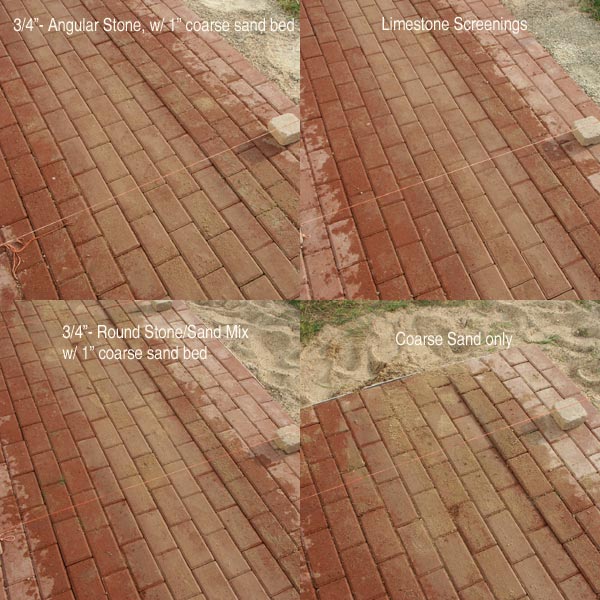

The test: We practical equal compaction to each base, screeded each to the exact aforementioned gradient. We then installed pavers over the area using the weakest interlocking pattern known; running bond. The objective was to make the conditions least optimal for these bases and the pavement, and then to strength failure to see which would agree up the longest.

To strength failure, we sprayed an equal amount of water over each pavement, and then immediately collection a small-scale vibratory compactor in a direct line across all four areas. The h2o acts as a lubricant, assuasive stone particles to shift when forces are applied to them. The same matter happens when you walk on your patio during or afterwards a rain.

We performed many iterations of spray-and-meaty to provide years worth of wearable in a unmarried afternoon, until we had articulate winners and losers.

The winner? The base preparation method we'd been using all along, which was 7″ of screenings. It showed the least amount of settling and displacement post-compaction. Second place was the base that used half-dozen″ of crusher run and an inch of sand.

Not Resting On Our Paver Laurels

The fact that our preparation method won the test was squeamish, but information technology didn't mean there weren't lessons to be learned and changes to exist made in how we prepare the foundation of the paver projects we install across the Play tricks River Valley. The reason the sand-over-stone base preparations failed earlier is considering of the sand. Coarse or not, sand particles are just not large enough to resist moving when forces are practical to them. Always walk barefoot on a beach? Where does the sand get? Between your toes, right?

The crushed rock beneath that sand is solid. Unmoving when the force of feet or small vehicles are applied to it. And when it comes to strength resistance and forcefulness of interlock, large athwart stone trump pocket-size angular stone every time. So the sub-base of the crusher base preparation was stronger than that of the screenings base training, but made weaker overall by the sand bedding form on top of it.

From that exam nosotros changed how we installed our pavements, taking the best of these top two methodologies to create a "Superbase": Crusher run sub-base under a screenings upper base. The outcome is something stronger than anything whatsoever of our competitors are installing in our expanse.

Source: https://stonehengebpl.com/best-paver-patio-base-preparation/

0 Response to "what kind of stone to use for paver base"

Post a Comment